It has now been two months since the US Food and Drug Administration (FDA) published its final rule amending the Current Good Manufacturing Practice (CGMP) requirement of the Quality System Regulation (QSR) (21 CFR Part 820) to incorporate by reference, and thereby align more closely with, the international consensus standard ISO 13485:2016, Medical devices—Quality management systems—Requirements for regulatory purposes. The new regulation, referred to as the Quality Management System Regulation, or QMSR for short, is the medical device industry’s latest significant regulatory change and move towards more consistency in the global regulatory framework. With the publication of the final rule, the FDA have provided additional clarification and information so manufacturers may start to plan implementation strategies ahead of the effective date of 2 February 2026.

Compliance Navigator Blog

Updates and commentary on the new Medical Devices / IVD Regulations and innovations in the medical device industry.

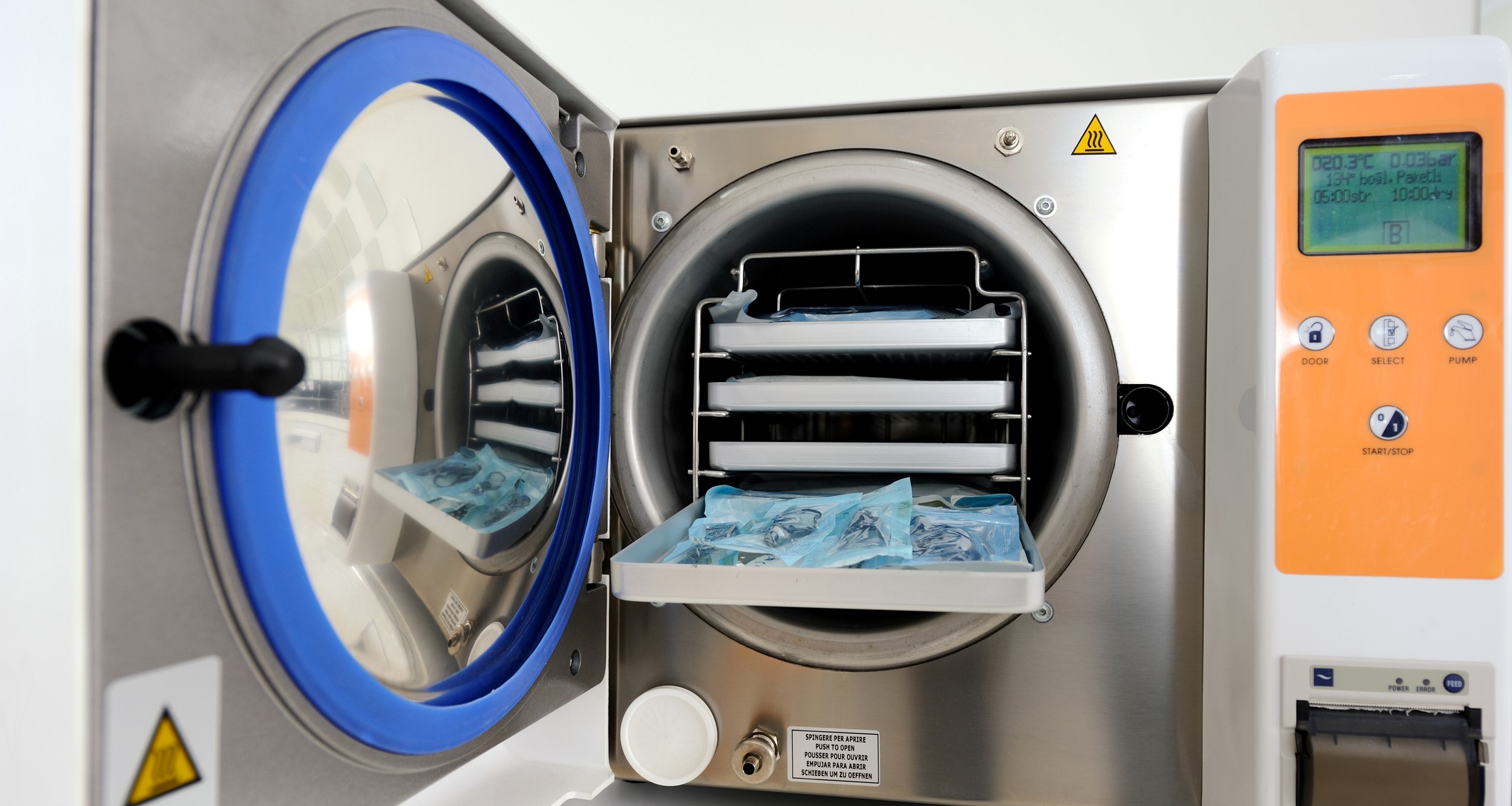

US FDA recognition of Vaporized Hydrogen Peroxide sterilization as Established Category A method

Over the past years, the US FDA has announced a number of initiatives, including Ethylene Oxide (EO) Innovation Challenges and Master File Pilot programs, to advance innovation and streamline the regulatory pre-market approval process. On 8 January 2024, the US FDA announced the re-issue of the guidance titled “Submission and Review of Sterility Information in Premarket Notification (510(k)) Submissions for Devices Labeled as Sterile”, superseding its 2016 version. In this blog, we will explore what are the significant changes in the guidance; what prompted these changes; and what are the implications for medical device manufacturing.

FDA and ISO 13485 – Cause for Concern or Celebration?

After years of speculation by the medical device community, on 2 February 2024, the US Food and Drug Administration (FDA) published its final rule amending the current good manufacturing practice (CGMP) requirement of the Quality System Regulation (QSR) to incorporate by reference, and thereby align more closely with, the international consensus standard ISO 13485:2016, Medical devices—Quality management systems—Requirements for regulatory purposes. The new regulation is called the Quality Management System Regulation (QMSR) Final Rule and is the latest significant regulatory change affecting the global medical device industry.

Embracing sustainability and the circular economy in the medical device industry: Understanding the differences

The medical device industry is immersed in innovation, consistently pushing the boundaries of what is possible in healthcare. Amidst these advancements, two essential concepts have emerged that are seen as both enablers and inhibitors to innovation: Sustainability and the circular economy. While often used interchangeably, they represent distinct approaches to addressing environmental, economic, and global supply chain challenges. In this blog, we will explore the key differences between sustainability and the circular economy in the medical device industry.

Regulation of Medical Devices and In Vitro Diagnostic Medical Devices in Northern Ireland

The regulation of medical devices and in vitro diagnostic (IVDs) medical devices in Northern Ireland is governed by the Windsor Framework. This means that the EU Medical Device Regulation ((MDR)(EU) 2017/745 and In Vitro Diagnostic Medical Device Regulation (IVDR) (EU) 2017/746 have applied in Northern Ireland in line with the respective dates of application across the EU. The Medicines and Healthcare Products Regulatory Authority (MHRA) is the de facto Competent Authority for Northern Ireland and has specific requirements for registration, vigilance reporting etc.

Steps towards compliance with EN 60601

Did you know that EN 60601 is part of several schemes globally

Do you know what the requirements of the EN 60601 are

EN 60601 specifies a set of requirements that medical electrical equipment and systems must meet to ensure safety and essential performance. The specific requirements vary depending on the part and edition of the standard. Below you can find an overview of the general categories of requirements covered by EN 60601:

What is 60601 - all you need to know

IEC 60601 refers to a series of international standards that pertain to the basic safety and essential performance of medical electrical equipment. These standards are issued by the International Electrotechnical Commission (IEC), a global organization that develops and publishes international standards for electrical, electronic, and related technologies and has been adopted by CENELEC without technical modification for use in Europe where it is designated EN 60601.

The Differences and Similarities between ISO 9001:2015 and ISO 13485:2016 | Part 2

It has been more than 6 years now that ISO 9001 has been using the High-Level Structure (HLS) as outlined in the ISO/IEC Directive, Part 1. There have not been any significant problems created by the divergence of the two standards. In this update we will discuss the current activities by both Technical Committees and other activities by the ISO organization and others that could be of significance. While there are still many people that focus on the differences, it is clear that the standards continue to be used alongside each other without significant issues as there remains no direct conflict between the requirements. In part 2 of the series, we're focussing on the similarities between the two standards and summarising our main points.

The Differences and Similarities between ISO 9001:2015 and ISO 13485:2016 | Part 1

It has been more than 6 years now that ISO 9001 has been using the High-Level Structure (HLS) as outlined in the ISO/IEC Directive, Part 1. There have not been any significant problems created by the divergence of the two standards. In this update we will discuss the current activities by both Technical Committees and other activities by the ISO organization and others that could be of significance. While there are still many people that focus on the differences, it is clear that the standards continue to be used alongside each other without significant issues as there remains no direct conflict between the requirements.

International regulatory recognition in the UK

On 7th March 2023, the Medicines and Healthcare products Regulatory Agency (MHRA) advisory group proposed a significant regulatory reform. [1] Its proposal is to build "… on current product recognition routes from the EU, [and to] rapidly explore building a UK product regulation equivalence route for the approvals of medical devices to include other trusted jurisdictions such as the US for a greater proportion of products." What does recognition mean for UK patients and for the HealthTech industry in the UK?

Update on the UKCA Mark: a rapidly evolving landscape

The Medicines and Medical Devices Act 2021 [1] gave legal power to the Medicines and Healthcare products Regulatory Agency (MHRA) to set up a new United Kingdom (UK) regulatory framework for medical devices and in vitro diagnostic devices (IVDs). This new primary legislation paved the way for the MHRA to update the existing secondary legislation - the UK Medical Devices Regulations 2002 [2]. According to the 2021 Act, new regulations must safeguard public health and, at the same time, have regard to the safety and availability of devices. The Act also means that new regulations must also make the UK a favourable place to research, develop, manufacture and supply medical devices. It is a requirement that the MHRA must carry out a public consultation before updating these and any future regulations.

The EU Product Liability Directive and its relationship with the MDR and IVDR

The Medical Device Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR) reference several other directives and regulations. One such directive is the Product Liability Directive (PLD). Published in 1985, the PLD is a well-established mechanism for ensuring that manufacturers shall be liable for damage caused by a defect in their product. There are two important updates currently under consideration within the EU that could impact medical device manufacturers and patients alike.

Discussion-Ethical and trustworthy Artificial Intelligence

The application of the AIA is expected to have a global effect as it has a horizontal applicability across industries, it covers all providers and users where the output of the AI system is used in the EU, and standardization creates harmonization increasing business opportunities for large markets such as the EU.

Prohibited Artificial Intelligence Practices, Classification (Art. 6) and Requirements (Ch. 2)

The EU legal framework was built around the notion that AI should be Ethical and Trustworthy. It is not therefore a surprise that AI practices that contradict basic human rights are considered prohibited. AIA (Council, Nov 2022)(Article 5) prohibits AI practices that might lead to physical or phycological harm (Fig. 1).

Definition of AI

The definition of AI is important as it will dictate the products that fall under the scope of AIA, as well as filtering out products using the term AI incorrectly. A global concern on the definition of AI has been raised, leading to a broad range of definitions in official documents. Some of which are presented in Table 1 - Definitions (TC260, 2021) that make use of the term “intelligence”. These are ambiguous however, as there is no globally accepted definition of intelligence (Shane Legg, 2007) (Wang, 2019).

Transitioning from IVDD to IVDR

The transition period for the IVDR has now begun. The initial timeline for date of application, on 26 May 2022 (after which, no new IVDD certificates can be issued), has been partially extended to allow manufacturers to continue to sell “legacy” devices already placed on the EU market for up to an additional 5 years, depending on the risk class, as long as no significant changes are made to the device design or intended purpose. Any new devices placed on the market will need to conform to the revised rules of the IVDR.

The Medical Device Single Audit Program (MDSAP) audit approach document updated

Changes introduced in the instructions for MDSAP audits The Medical Device Single Audit Program (MDSAP) was developed to conduct regulatory audits of quality management systems (QMS) of manufacturers of medical devices. The MDSAP allows a single audit conducted by a recognized Auditing Organization (AO) to cover the requirements of BS EN ISO 13485:2016, together with specific regulatory requirements for the participating jurisdictions – Australia, Canada, Japan, Brazil and USA. Participation in the programme should reduce the need for duplicate audits and reduce the resource requirements on Regulatory Authorities and medical device manufacturers. Audits conducted in the MDSAP follow a prescribed process of defined tasks that the auditors have to perform. The audit tasks that have to be covered and the links to the applicable regulatory requirements for participating jurisdictions are identified in the MDSAP Audit Approach (MDSAP AU P0002). The 2023 update, issued in March, takes the document to revision 008.

European Union extends validity of certificates issued under Medical Devices Directives

Extension to EU Directives certificates will also apply in Great Britain and Northern Ireland To maintain patients’ access to a wide range of medical devices while ensuring the transition to the new regulations, the European Union has taken action to extend the validity of certificates issued under the Medical Devices (Directive 93/42/EEC) and Active Implantable Medical Devices Directives (Directive 90/385/EEC). The changes have been implemented by Regulation (EU) 2023/607 of the European Parliament and of the Council of 15 March 2023 amending Regulations (EU) 2017/745 and (EU) 2017/746 as regards the transitional provisions for certain medical devices and in vitro diagnostic medical devices.

New product development

Technical documentation

The regulations define additional detail for the content of the Technical Documentation – often referred to as the Technical File – for each medical device or family and require that the information is presented in a clear, organized, readily searchable and unequivocal way. The regulations also reinforce the emphasis on the requirements driving a lifecycle approach to the management of the medical device with the routine updating of the Technical Documentation, including:

Guidance published on quality of water for sterilizers and washer disinfectors

The Technical Committee responsible for standards on sterilization and washer disinfectors, ISO TC 198 – Sterilization of health care products – has a portfolio of standards that cover validation and routine control of sterilization processes, general requirements for sterilizers and standards for washer disinfectors. On January 2021, the committee published its first standard for sterilizing equipment; ISO TS SO/TS 22421:2021 - Sterilization of health care products — Common requirements for sterilizers for terminal sterilization of medical devices in health care facilities.

European Commission proposes action on transition to the Medical Devices Regulation

The European Commission’s Medical Device Coordination Group (MDCG) survey on notified body certification and application activities under the Medical Devices Regulation (EU 2017/745) (MDR) and In Vitro Medical Devices Regulation (EU 2017/746) (IVDR) showed the problems in the transition to the MDR and IVDR. A significant number of certificates for legacy medical devices expire on 26 May 2024.

Recognition of European Standards to support Medical Devices Regulations progresses

European Commission set to add to list of Harmonised Standards in the Official Journal Harmonized European Standards have an important, specific role in supporting the European Regulations for medical devices (MDR) and in vitro diagnostic medical devices (IVDR). Article 8 of each Regulation indicates, that Harmonized Standards referenced in the Official Journal (OJ) of the European Union, provide a presumption of conformity with relevant requirements of the Regulation covered by those standards or applicable parts of standards. The presumption of conformity also applies to system or process requirements, including those requirements relating to quality management systems and risk management.

Overview of main changes brought about by the IVDR

The IVDR shares many of its new features with the MDR (EU regulation 2017/745). Apart from the new elements shared with the MDR and the consequences for the market entry and surveillance (like the new supply chain regime, use of unique device identifiers (UDI) and a central database that is the European database on medical devices (EUDAMED)), there are three major reforms in the IVD field:

Will the EU Medical Devices Regulations certificate cliff edge in 2024 be avoided?

European Commission propose action as survey indicates that large majority of MDR certificates expire in 2024 The European Commission’s Medical Device Coordination Group (MDCG), has undertaken a survey to collect data on notified body certification and application activities under the Medical Devices Regulation (EU 2017/745) (MDR) and In Vitro Medical Devices Regulation (EU 2017/746) (IVDR).

Risk management by BS EN ISO 14971

The risk management process described in BS EN ISO 14971 [1] consists of several steps, as illustrated in Figure 1, which apply to the design, development, production and post-production stages of every medical device. The distinct process steps are numbered from 1 to 6 and discussed in detail in this paper.

Relation of BS EN ISO 14971 with other standards

Implementation of revised UK Medical Devices Regulations delayed

Performance evaluation plan

Although the concept and requirements of performance evaluation have not really changed over 20 years, the required technical documentation has changed radically both in terms of content and amount required in the IVDR compared to the IVDD. The contents of two new IVDR documents are explicitly described in Annex XIII: the performance evaluation plan (PEP) and the performance evaluation report (PER).

Notified Body surveillance of legacy devices under the IVD Regulation

EU issues guidance on surveillance of IVDs on the market with certificates under the Directives The In Vitro Diagnostic Medical Devices Regulation (IVDR) (EU 2017/746) permits devices covered by valid certificates issued by a Notified Body under the IVD Directive (98/79/EC) to be placed on the market or put into service after the date of application of the IVDR, and no later than 26 May 2025, under certain conditions. This is covered by the transitional provisions in Article 110(2) and 110(3) of the IVDR. The guidance describes such devices with the term ‘legacy devices’.

FDA finalises guidance on electronic 510(k) submissions

The FDA launched a pilot programme for electronic premarket submissions to demonstrate that the device to be marketed is substantially equivalent to a legally marketed device, known as 510(k) submissions. This was known as the eSubmitter electronic submission template. This pilot programme ended in May 2021.

Analytical performance

Analytical performance is not a new concept for IVDs, having been described in the IVDD since 1998. Many of the same analytical performance characteristics are present in both IVDD and IVDR, but IVDR seeks to expand on what nature of data should be provided. Section 9.1 of Annex I describes the analytical performance requirements, but as all scenarios of device type and intended purpose cannot be anticipated, the onus is on the manufacturer to provide a rationale for any characteristics that are not applicable to their device.

US FDA issue draft guidance for industry on conducting remote regulatory assessments

The US FDA has issued draft guidance, in the form of a Question and Answers document, on conducting remote regulatory assessment (RRA). The draft guidance is intended to provide transparency and greater consistency. The guidance notes that practices adopted during the pandemic for remote interactions have proven useful in reducing delays in approval or authorization of marketing submissions. They have also been valuable in:

Updated guidance on implementation of EU product rules

For those with long memories, the ’Blue Guide’ represents the descriptor for the UK Department of Health ‘Guide to Good Manufacturing Practice (GMP) for sterile medical devices’. This was first published in 1979 and updated in 1981 and 1990. This ‘Blue Guide’ was one of a series of rainbow-coloured GMP documents for specific types of medical devices that were replaced first by the BS EN 46000 series of standards and supporting guidance documents, where EN 46001 was Quality systems - Medical devices - Particular requirements for the application of EN ISO 9001, and ultimately EN ISO 13485 - Medical devices — Quality management systems — Requirements for regulatory purposes.

Performance evaluation under IVDR

FDA proposes Standards Recognition Program for regenerative medicine therapies

Manufacturers urged to action on MDR implementation

Further amendment to lists of harmonised standards

The European Commission has published the second amendments to the lists of harmonised standards in the Official Journal of the European Communities (OJ). Harmonised standards listed in the OJ provide a presumption of conformity with the with relevant requirements of the Medical Devices Regulation (MDR) and In Vitro Diagnostic Medical Devices Regulation (IVDR) covered by those standards or applicable parts of standards...

Understanding the borderline between medical devices and medicinal products

Development of standards

Standards are used to support the regulatory process because they are developed in accordance with set principles of transparency, openness to participation by interested stakeholders, balance of representation and due process. The way that standards are developed is intended to assure that, while many interests are considered, no single party wields disproportionate influence.

Standards and the state of the art

Consolidated text of UK Medical Devices Regulations released

US proposal to align with ISO 13485 hits the press

UK designated standards

It is important to be aware that the MDR and IVDR will not be implemented in England, Scotland and Wales. In this context, the distinction between Great Britain (GB) – England, Scotland and Wales – and the United Kingdom, which comprises Great Britain and Northern Ireland, is relevant. Northern Ireland will have a special status as EU rules will continue to apply there. The Northern Ireland Protocol is a key part of the agreement on the UK withdrawal from the European Union. The effect of the Northern Ireland Protocol is that products on the Northern Ireland market, including medical devices, are required to comply with EU Regulations and Directives as well as with UK law. Separate requirements regarding CE marking will apply in Northern Ireland.

QMS and pre-market clinical investigations

It can be anticipated that most manufacturers will demonstrate compliance with the MDR by means of conformity assessment based on a QMS and assessment of technical documentation, as specified in MDR Annex IX. Section 2.2(c) requires that the documentation to be submitted for the assessment of the QMS includes an adequate description of: the procedures and techniques for monitoring, verifying, validating and controlling the design of the devices and the corresponding documentation as well as the data and records arising from those procedures and techniques. Eight different elements that the procedures and techniques need to address are specified and, in brief, are...

MDR requirements for PMCF investigations

European standard for risk management of medical devices is amended

EU adopts progressive roll-out of the In Vitro Diagnostic Medical Devices Regulation (IVDR)

Updated requirements and guidance on symbols for use with medical devices

Guidance on the Medical Device Single Audit Program (MDSAP) updated

MDR clinical evaluation planning - intended purpose, indications, contraindications

Purpose of a clinical evaluation under the EU MDR

The purpose of the clinical evaluation is to demonstrate, with objective and scientifically valid evidence, that the device does what it is supposed to do, achieves its intended clinical benefits (whether direct or indirect) and that the benefit-risk conclusion is acceptable in comparison to other available therapeutic or diagnostic options.

Clinical evaluation under EU MDR

Consultation on revising UK medical devices regulations initiated

European amendment published for medical devices quality management system standard

Why was the requirement for an SSCP introduced?

EUDAMED and legacy devices

EUDAMED and the UDI and Device Registration module

Overview of the EU Basic UDI-DI

First lists of harmonized standards published for Regulations for medical devices

Guidance on integrating Unique Device Identification into your Quality Management System

Standardization request approved for standards to support regulations for medical devices

A Standardization Request from the European Commission to the European Standards Organisations , CEN and CENELEC, provides the legal basis for harmonising standards. Agreement of this request allows publication of references to harmonised standards that provide a presumption of conformity under the MDR and IVDR to start.

Final updates to the list of standards harmonised for the European medical devices directives

Three Commission Implementing Decisions for harmonised standards were adopted in April 2021 and published in the Official Journal. There is a separate decision for each of the three directives. These implementing decisions present the final updates to the list of harmonised standards that give a presumption of conformity for the directives for medical devices.

Consultation on new guidelines for the application of ISO 14971 to artificial intelligence and machine learning

BS AAMI 34971 Guidance on the Application of ISO 14971 to Artificial Intelligence and Machine Learning is a guidance document for applying a risk management process when evaluating medical technologies that utilise artificial intelligence (AI) and machine learning (ML). This guidance document will address the same types of risk that are already covered in ISO 14971, but it focusses on those risks that are elevated or unique to AI-based medical devices.

An overview of drug-device combination products in the EU

Standards and the state of the art for medical devices regulation

The Medical Device Coordination Group (MDCG) is composed of representatives of Member States and chaired by the EU Commission. The MDCG has issued a guidance document on standardization for medical devices. As with all the MDCG guidance, it cannot be regarded as reflecting the official position of the European Commission, or as being legally binding.

Six steps to implement a revised standard successfully

The manufacturer has responsibility for the legal compliance of products intended to be placed on the market. Within this responsibility, the manufacturer has the choice of whether or not to use a particular standard. The manufacturer also needs to be able to demonstrate how they have “taken into account” the state of the art. Given that there have been a number of statements that the most recent published editions of standards should be considered as reflecting state-of-the-art, this suggests that manufacturers should give consideration to the latest version of a relevant standard, even if it is not harmonized.

Manufacturers who need to appoint a person responsible for regulatory compliance (PRRC)

As per the Regulations Article15(1) and as interpreted by the MDCG Guidance 2019-7, manufacturers are required to have available within their organisation at least one PRRC with proper expertise in the field of medical devices or in vitro medical devices, as applicable, in the European Union. This is valid for enterprises which employ at least 50 persons and whose annual turnover and/or annual balance sheet total exceeds EUR 10 million.

Person responsible for regulatory compliance (PRRC) - MDR/IVDR Article 15

With the Medical Device Regulation – MDR (EU 2017/745) and In Vitro Diagnostic Regulation – IVDR (EU 2017/746), European regulators aim to ensure companies have a regulatory expert – a Person Responsible for Regulatory Compliance (PRRC) – at their disposal, to ensure that the company is meeting certain specific EU requirements.

Updated standard specifies test method for packaging of terminally-sterilized devices

An effective sterile barrier system is essential to maintain the sterility of terminally sterilized medical devices. BS EN ISO 11607-1 - Packaging for terminally sterilized medical devices — Part 1: Requirements for materials, sterile barrier systems and packaging systems - specifies requirements for materials and pre-formed systems intended for use in packaging systems for terminally sterilized medical devices. BS EN ISO 11607-2 - Packaging for terminally sterilized medical devices — Part 2: Validation requirements for forming, sealing and assembly processes - describes the validation requirements for forming, sealing and assembly processes.

UK lists of designated standards for medical devices published

Following the end of the Brexit transition period, the EU Medical Devices Regulation (MDR) and In Vitro Diagnostic Medical Devices Regulation (IVDR) will not be implemented in England, Scotland and Wales. The UK Medical Devices Regulations 2002 (SI 2002 No 618, as amended) continue to have effect. The UK Conformity Assessment (UKCA) mark will apply to medical devices, including in vitro diagnostic medical devices. Northern Ireland will have a special status as EU rules will continue to apply there.

UK Conformity Assessment (UKCA) marking comes into effect

Following the end of the Brexit transition period, the EU Medical Devices Regulation (MDR) and In Vitro Diagnostic Medical Devices Regulation (IVDR) will not be transposed into law in Great Britain. In this context, it is important to be aware of the distinction between Great Britain – England, Scotland and Wales – and the United Kingdom, which comprises Great Britain and Northern Ireland. The MDR and IVDR will not be implemented in England, Scotland and Wales. Northern Ireland will have a special status as EU rules will continue to apply there.

Instructions for use for reusable medical devices

The Compliance and Enforcement Group (COEN) provides exchange of information between Competent Authorities (CA) responsible for market surveillance (MS) of medical devices (MD) and coordinates their enforcement activities. COEN created a working group to address nonconformities under the Medical Devices Directive related to the instructions for use (IFU) for resterilizable devices.

Medical Device Single Audit Program (MDSAP) updates audit process

New guidance on parametric release for ethylene oxide sterilization

EN ISO 11135 - Sterilization of health-care products — Ethylene oxide — Requirements for the development, validation and routine control of a sterilization process for medical devices – specifies requirements, and provides guidance, for development, validation and routine control of ethylene oxide (EO) sterilization processes. EN ISO 11135 was published in 2014 and an amendment to the standard was adopted in 2019.

Types of medical software

The FDA has defined stand-alone medical software in the Preamble Section AA Special Requirements for Stand-Alone Software—Final § 801.50 of the Unique Device Identification (UDI) System Regulations as ‘medical software that is itself a medical device and is not a component, part, or accessory of a medical device’.

IVDR: Practical Considerations for the Performance Evaluation Plan and Report

Guidance issued on process control for sterilization using ionizing radiation

An introduction to SaMD

Using the Medical Device Single Audit Program (MDSAP) to support EU regulatory requirements

MDR requirements for PMCF investigations

Developments in the standardization request for harmonized standards

Clinical investigations and the MDR: SAE reporting to Member States

UK guidance on stand-alone medical device software including apps issued

Clinical investigations and the MDR: sponsors and legal representatives

New international specification gives general requirements for sterilizing equipment

The delivery of a validated and accurately controlled sterilization process is enabled by the use of sterilizing equipment that is designed, constructed and installed to deliver the sterilization process safely and reproducibly. There are currently no international standards for sterilizing equipment.

Innovation in regulatory approaches to AI

MDR requirements for pre-market clinical investigations – General considerations